Casella UK

Wolseley Rd, Kempston,Bedford MK42 7JY

+44(0)1234844100

info@casellasolutions.com

It is often said that the US and UK are two nations divided by a common language and to some extent that is also true when it comes to the structure and enforcement of their respective health and safety legislation, monitoring strategies, sampling methods and limit values.

The UK CoSHH [1] Regulations are quite clear when it comes to the need to monitor for airborne hazards i.e.

In the US, both guidelines and exposure limits are embodied in the relevant parts of the same Federal Regulations [2] while methods may be found in the NIOSH manual of analytical methods [3], the latter equivalent to HSE publication HSG173 [4] and accompanying Methods for the Determination of Hazardous Substances (MDHS) series [5], while the WELs themselves are published in EH40 [6].

Both real-time direct reading instruments and personal air sampling pumps are commonly used for workplace exposure monitoring to assess potential hazards to workers' health. Each method has its advantages and limitations, and the choice between them depends on various factors such as the specific contaminants being monitored, the nature of the workplace environment, the desired level of accuracy, and the resources available.

The two countries ‘agree’ on deploying personal air sampling pumps, the occupational (aka industrial) hygienists’ mainstay tool of the trade for compliance monitoring. The pump is attached to a worker (typically on a belt) with a suitable sampling medium placed in their breathing zone e.g. a filter housed in a sampling head and run over sufficiently long time to establish an accurate concentration value which can then be compared with the WEL. The respective ‘official method’ will advise on the type of filter and sampling head (or tube for vapours) for the given hazardous substance along with the required flow rate and minimum run time.

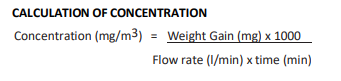

It is vital that the pump has a stable flow rate (and low pulsation) as required by international standard ISO 13137 [7], because the calculated concentration in the case of particulates is directly proportional to the weight of the sample and inversely proportional to the flow rate as shown:-

The two countries also concur over the use of local exhaust ventilation (LEV) as a common control method.

In the US, ventilation regulations are contained as a subpart [8] of the above-mentioned Federal Regulations which reference ANSI design standards [9]. In the UK, best practice is contained within HSG258 [10] and CoSHH Regulation 9 requires testing by a competent person as a legal requirement specifically to examine, maintain and test LEV systems at least every 14 months.

It may seem somewhat archaic to sample something for a whole shift, then wait to get the results to know an individual’s exposure. Direct reading devices that provide a real-time concentration have an obvious advantage. Many such devices use a light scattering technique which can, however, be influenced by the shape and texture of the dust, so unless they have been specifically calibrated for the dust in question, they should only be considered as indicative. Its rather like trying to weigh someone using a torch!

In summary, both real-time direct reading instruments and personal air sampling pumps have their place in workplace exposure monitoring programs. Real-time instruments offer immediate feedback and continuous monitoring capabilities but may lack specificity. Personal air sampling pumps provide accurate quantitative data suitable for regulatory compliance but involve delayed results and require more effort in sample collection and analysis. The choice between the two methods depends on the specific monitoring needs, budget considerations, and available resources. Casella publish a very useful resource which expands on many of the points raised in this article Air Sampling Handbook 2022 (casellasolutions.com)