Casella UK

Wolseley Rd, Kempston,Bedford MK42 7JY

+44(0)1234844100

info@casellasolutions.com

In recent articles [1] [2], we looked at chronic obstructive pulmonary disease (COPD) it’s potential causes including smoking, a rare genetic defect and in particular, workplace exposure plus the resulting severe health effects. We also looked at two methods for quantitative risk assessment namely a real-time, walk-through survey and longer term, personal sampling. This article will look at the features and benefits of two instrument solutions: the Microdust Pro and Apex2 Personal Air Sampling Pump.

| The current, third generation design remains popular in part because of its wide range from 0.001 mg/m3 to 250g/m3 which means that this versatile instrument can be used for applications ranging from walk-through surveys to testing local exhaust ventilation (LEV) performance. Its auto ranging feature means there is no need to set the range beforehand and risk an under or over estimation of the dust concentration. Another valued feature is its removeable probe, significantly smaller and lighter than the previous version, the two-part design meaning that the probe can be held in one hand and the main instrument body comfortably in the other, which itself is also smaller and lighter reducing the burden during field use. |

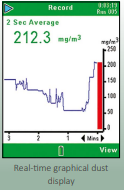

A more lightweight, separate probe on a retractable curly cable means you can get easy access to hard-to-reach spaces or even in ducts for example, as is often required for LEV checks A full-colour display makes for easy use and as well as an alpha-numeric display there is a graphical display which is useful for tracking spikes, trends and real-time effects of making adjustments to control methods. |  |

| The instrument is factory calibrated using a method traceable back to isokinetic techniques and is conducted in a custom-built wind tunnel using ISO 12103-1 A2 Fine test dust (Arizona road dust equivalent). Each probe is also supplied with its own unique Calibration Insert, which creates a known optical scattering effect in the probe’s sampling chamber. This fixed reference can be used to confirm the original factory calibration point, although annual factory recalibration is recommended. |  |

While the Microdust Pro comes factory calibrated, by using an Apex2 Air Sampling Pump and gravimetric adaptor, user-defined dust-type settings may be obtained. This means that the user can calculate a correction factor for the actual type of dust being measured and ensures maximum accuracy for a particular application.

Using this widely accepted, benchmark assessment method, a known volume of air is drawn through a pre-weighed filter at a constant flow rate using a pump. Weighing the filter before and after sampling determines the mass of dust collected and by dividing that mass by the total volume of air drawn through the filter, an average airborne dust concentration is obtained for the sampling period. Apex2 is just a pump then?

It’s been said many times in previous articles that the pump must conform to a relevant standard [3] and balancing the requirements of flow control, back pressure capability, low pulsation, intrinsic safety approval and battery life is something of a design challenge. So much so, the latest 2022 revision has relaxed the pulsation requirement from 10 to 12%, one can speculate why, but for the record Apex2 easily met the ‘old’ 10% requirement. Speaking of intrinsic safety, the all three models of Apex2 (Standard, Plus & Pro) are approved as standard to Ex ia IIC T4 Ga, Ex ia IIIC T135°C Da and Ex ia I Ma specifically for mining applications.

Meeting these requirements is a ‘must have’ expectation but there are many other practical aspects to the Apex2 that have gone into making it an award-winning, patented design such as ergonomics and connectivity which are not covered by the standard. Take the Apex2’s shape for example. If the design had continued along traditional lines, it would have resulted in a portrait-like form factor like its predecessors, the TUFF and Apex and indeed probably as far back as Casella’s first, innovative pump way back in the 1960s, the prototype of which was housed in an old bicycle lamp!

As you can imagine, Casella has learned a lot in the intervening 60 years. Take the position of the screen for example. With a pump worn on a belt and a display screen located on the side it is more exposed and risks accidental damage, whereas putting it on the top means it is more protected. Features like the belt clip and inlet nozzle are also potentially going to get broken during the course of a pump’s life and they are, of course, field replaceable. The nozzle itself is recessed and a rubber boot is provided for further protection.

| Customer feedback during the concept stage of the development expressed a strong preference for the square form factor, which they felt was more comfortable to wear and less restrictive.

Getting the wearer’s buy-in in this way is very important to a successful sample, particularly if you only have a one-time opportunity to capture the data for example, during plant maintenance.

A nice feature ‘belt & braces’ feature is motion sensing which is a great way to check that the wearer didn’t ditch the pump the minute your back was turned; it does happen [4]! |

Plant turnaround can be a busy time with multiple pumps and other equipment such as noise dosimeters being deployed, and this was the inspiration for adding Bluetooth® connectivity. This allows you to remotely monitor (on Plus and Pro models) using the supporting Airwave software application on your phone or tablet and means you can view multiple pumps (and noise dosimeters) simultaneously without disturbing the wearers, to start and stop them remotely and to email data direct to your PC.

Whatever your application, Casella has an innovative solution and are busy working today for a healthier tomorrow.